To give you the best experience possible we have this website in your language: .

We will redirect you in: seconds

or you can click the button below to go now:

TOP QUALITY | TOP RELIABILITY

We are happy to announce that HC-CARGO can offer you a selected range of Bosch Drive belts.

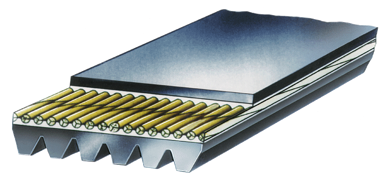

This gives you easier access to these quality products. Bosch drive belts are manufactured according to OEM quality and engine specifications. They are made of EDPM rubber (a synthetic rubber) giving the products even longer lifetime and better functionality ex. works resilient within temperatures from -40 to +130 Celsius.

And of course Bosch products are subjected to comprehensive testing and are constantly improved.

Benefits of the Bosch product range @ HC-CARGO

|

Bosch ribbed V-belts meet the current requirements placed on original equipment. That way, they are often an even better solution than the OE belts installed.

|

Bosch Drive belts are made of: Ethylene Propylene Diene Monomer (EPDM) which is a high-performance material.

(seen in comparison with chloroprene rubber (CR))

Avoid contact with oil or fuel

|

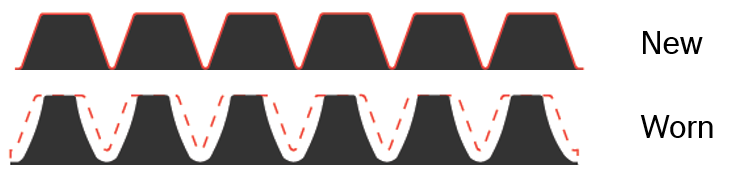

The power transmission between belts and pulleys takes place at the flanks (red) |

|

|

Wear: Mainly rib wear Consequence:

Aging effects such as cracking do not appear anymore with EPDM Bosch recommends: In order to ensure the optimum operational reliability, it is recommended to replace ribbed V-belts and timing belts at the same time |

|

They have the same characteristics as standard ribbed V-belts. Double ripped means they are able to power auxiliary units on both sides. Look for “DPK” coded products. |

|

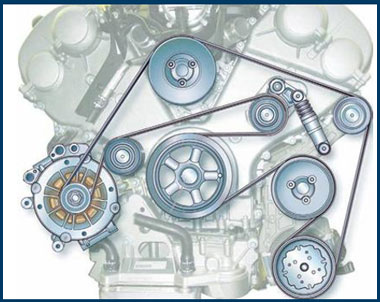

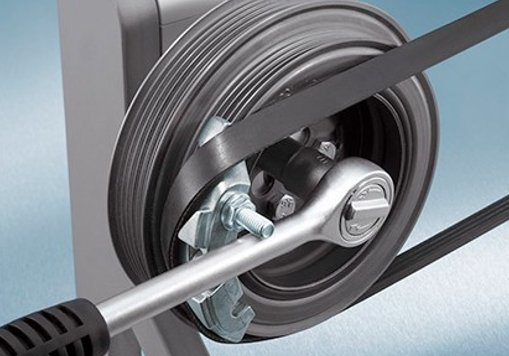

Ribbed V-belts Transmission of high torques by means of several smaller wedge flanks. Simultaneous powering of several auxiliary drives in combination with tensioner and idler pulleys. |

|

|

.

Click here to browse the whole range